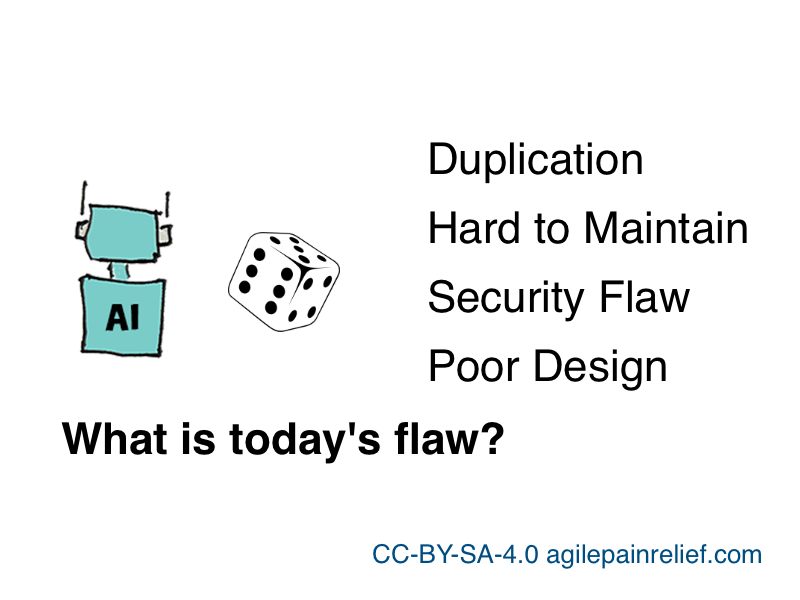

GenAI Code Quality – The Fundamental Flaws and How Bluffing Makes It Worse

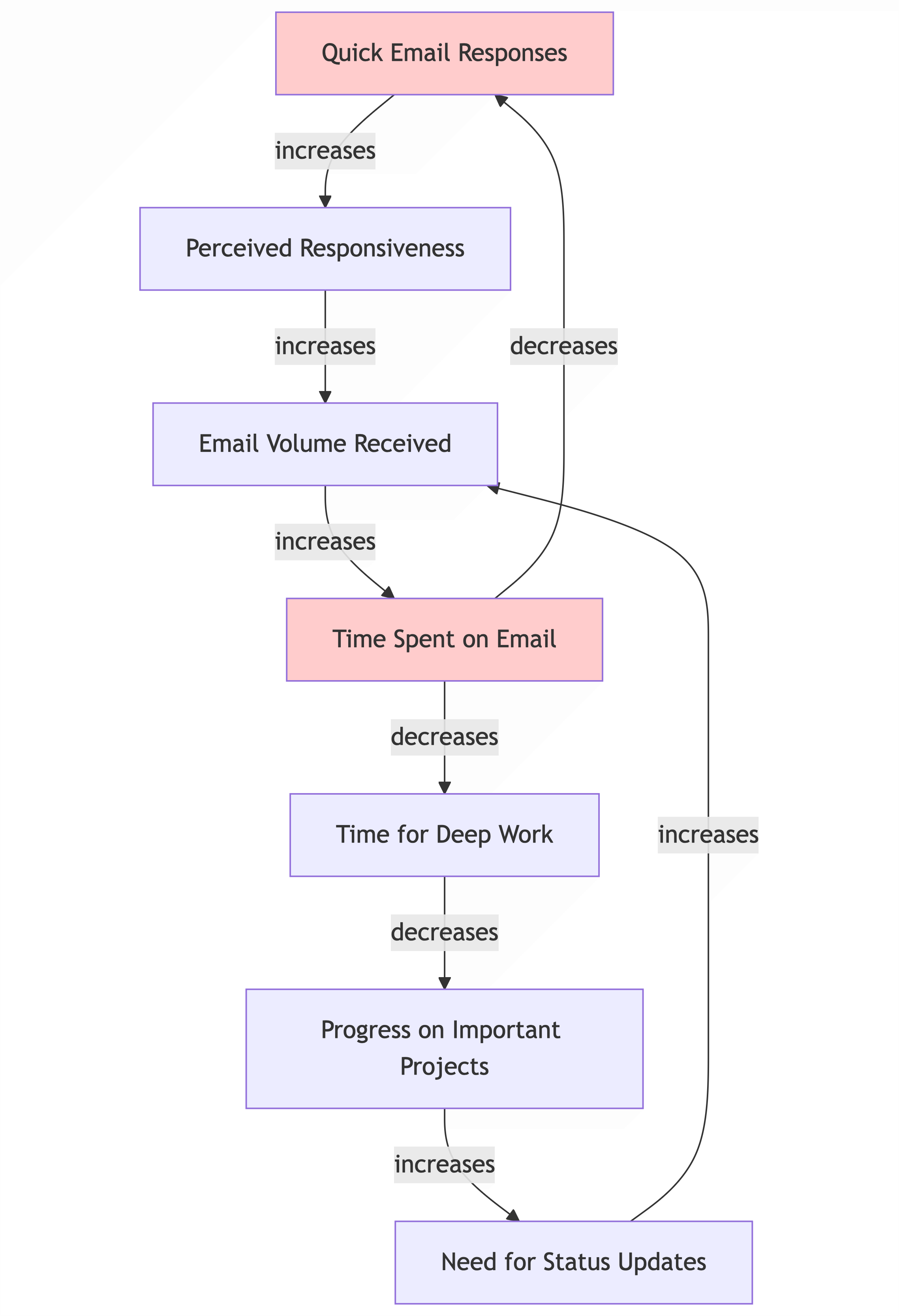

AI-generated code has 1.7x more issues and the flaws are structural, not fixable by code review. Why training rewards bluffing over quality, and what to do about it

Read full article